Comprehensive Quality Inspection Features

Everything you need for complete quality control automation in one powerful platform

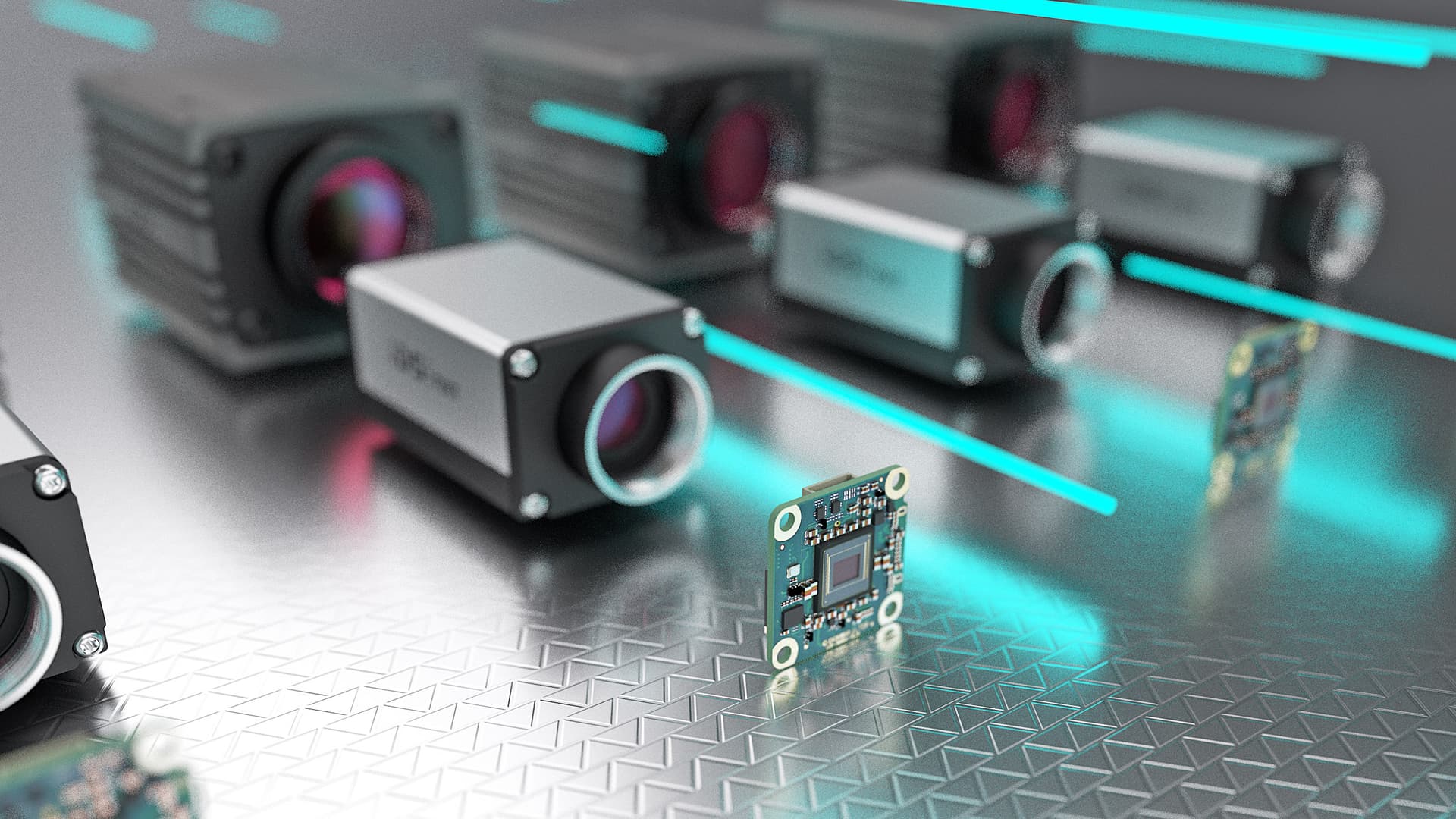

Inspect with Industrial Camera Setup

Fixed industrial cameras deliver highly consistent images with controlled lighting and angles — ideal for repeatable, high-precision inspections.

- Stable imaging with fixed orientation

- Best for high-speed lines & tight tolerances

- Works with standard industrial lighting rigs

- Quick calibration for new parts

Fixed Camera Station

Consistent angle, distance, and lighting every time.

High Precision Imaging

Ideal for tight tolerances and repeatable QA.

Quick Calibration

Swap parts and re-calibrate in minutes.

Enable Full Line Automation

Parts flow on the conveyor, PLC triggers image capture automatically, and Q100.ai sends instant pass/fail signals back to the line.

- Zero manual inspection effort

- PLC-based trigger ensures perfect capture timing

- Auto reject / diverter support

- Best for continuous high-volume production

PLC Trigger Capture

Auto capture synchronized with line signals.

Pass/Fail to Line

Send reject/divert commands instantly.

24/7 Analytics

Continuous quality trends from live production.

Capture Parts Using Any Mobile Phone

Q100.ai analyzes images perfectly even with hand movement or motion blur, delivering accurate and reliable inspection results anywhere.

- No expensive fixed camera setups required

- Credible results even if operator moves while capturing

- Flexible inspection at any production point

- Instant defect detection results on mobile devices

Portable Capture

Inspect anywhere on the shop floor without fixed stations.

Motion-Blur Tolerant AI

Accurate results even with hand movement.

Operator Friendly

Simple UI for fast adoption with minimal training.

Rapid 2-Hour Setup

Deploy Q100.ai at your production line with minimal downtime. Add new parts and be operational in just 2 hours.

- Pre-trained AI models for common defects

- Simple configuration interface

- No complex integration required

- Immediate ROI realization

100+ Detection Categories

Comprehensive defect detection covering the widest range of quality issues in manufacturing.

- Surface defects (scratches, dents, discoloration)

- Assembly errors and missing components

- Dimensional anomalies

- Contamination and foreign objects

Real-Time Detection

Lightning-fast inspection at production line speed without compromising accuracy.

- < 8s processing time per part

- Zero bottlenecks in production

- Instant pass/fail decisions

- Continuous learning from data

Easy Configuration

Intuitive interface for adding new specs and adjusting quality parameters without IT support.

- Visual configuration tools

- Template-based setup

- Multi-user role management

- Cloud-based updates

Compliance & Traceability

Complete audit trail with detailed QA reports for regulatory compliance and quality standards.

- ISO 9001 compliant reporting

- Automated documentation

- Batch traceability

- Custom report templates

Enterprise Integration

Connect seamlessly with your existing manufacturing infrastructure

PLC Integration

Seamless connection with major PLC brands for automated quality gates.

MES Connectivity

Direct integration with Manufacturing Execution Systems for data flow.

Analytics Dashboard

Real-time quality metrics and trend analysis for continuous improvement.

Ready to Transform Your Quality Control?

See Q100.ai in action with a personalized demo tailored to your production line

Request Your Demo Today